RFID and ble for goods management

Logistics and warehouse management

Why using RFID technology for logistics and warehouses?

Of all the technologies for automation and logistics, RFID technology can yield a great number of advantages. Thanks to its great flexibility, it allows to improve warehouse management and to obtain precise and real-time information on the production and the movements of goods.

Traditional warehouse management involves logistics and inventory operations that are high time demanding. Optical technologies such as barcodes are used - even if some less modern companies still use manual lists - to manage loading and unloading, shipments and incoming goods. This way of working greatly increases the risk of misalignment between the inventory and the moved goods. In a warehouse management system with RFID, logistics traceability is maximized: each pallet, package or product is equipped with an "intelligent" label. RFID logistics therefore allows you to speed up the flow of goods, minimizing manual operations and eliminating the cost of errors.

Obviously one tracking technology does not exclude the other! RFID and optical tracking technology could coexhist and even be complementary in some applications: RFID tags could be printed with the item information and its 1D/2D code. An example of RFID tags widely used in logistics is mother / daugher: a number of printed simple labels (daughters) are associated to a RFID tag (mother); this solution is perfect for those applications in which items and their documents must be tracked.

Automation of manual processes

Identification technologies automate time-consuming manual processes that carry a high risk of human error. Thanks to tracking systems, it is possible to minimize operating time and maximize the speed of production flow and management of goods.

Once the contents of a shipment have been detected, the generation of transport documents is done automatically and without errors. It seems like a small improvement but just think about the cost of a wrong shipment; in the best case the goods are collectable and reusable, while in the worst they cannot be recovered.

A solution for speeding up manual operations is Pick & Sort-to-Light, an evolution of logistics solutions for sorting and picking based on light signals; this, coupled with RFID technology, allows a further upgrade of warehouse management.

Real-time inventory thanks to RFID

Reading gates at the loading and unloading docks of the warehouse allows for instant inventory update as the goods enter and exit. Maximizing logistics traceability also involves great control over the intralogistics movement of goods, reducing problems such as loss or theft during transit and inconsistencies in transport documents.

Inventory is another critical operation; thanks to mobile devices that allow an average reading distance of 4-6 m and up to 15 m, it is possible to scan the entire warehouse area. The list of products can be drawn up quickly and efficiently. This operation allows the detection of any discrepancies between the stock and the inventory in real time.

Simplify logistics and production

The best RFID solution to enhance the warehouse management, logistics and production is the one that allows to trace every change of status and goods movements.

Production management

Other than tracking goods movements, it is possible to manage processings and production phases, automating the labeling process directly in-line.

The integration of an inline labeling system is non-invasive and allows to manage production in all of its phases and add a control step to the tracking system. Based on the application conditions, an RFID labeler allows to link the item tag to the production batch and get a trace of it if any problems arise.

Finally, the integration of a association tunnel at the end of the production line allows to check and validate the conformity of the item and of its batch; this way, outgoing parcels are 100% up to the standards.

Reading systems

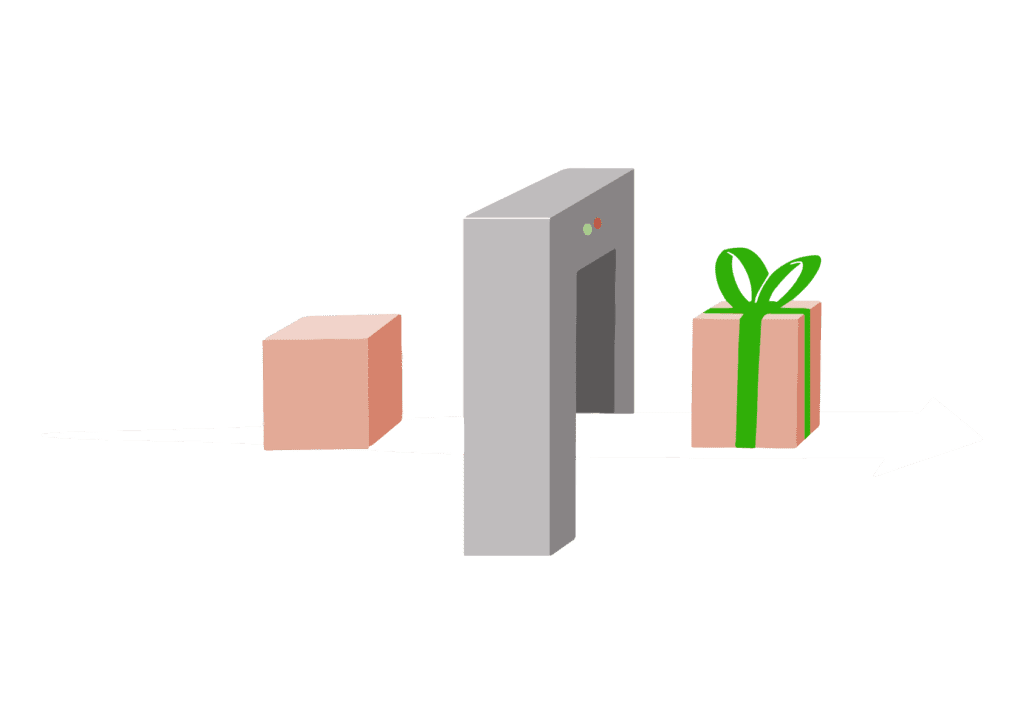

The main hardware solution for RFID systems for logistics is the gateway: a portal through which goods pass and are instantly detected. The gates are positioned at strategically in the warehouse – the choke points – and at the loading / unloading docks for reading the outgoing / incoming goods.

Operators can also be equipped with mobile devices – such as a handheld or a tablet –or wearable devices – such as a glove – for greater flexibility in reading and writing operations.

RFID tags

The complete integration of an RFID system for logistics may require different types of devices and tags, depending on the desired system and the flow of goods within the warehouse complex.

In logistics, in fact, objects might be stored outside, or in metal material. This is why over the years, EasyRFID has developed and tested special application products, such as the semi-rigid tag for outdoor use, the flag tag for situations where there is a risk of crushing and the anti-metal rigid tags.

Advantages over optical tracking technologies (barcode, QRcode,...)

Being the functioning of barcode technology very similar to that of RFID, it is often chosen as an alternative to passive RFID tag technology.

If on one hand RFID technology involves a larger investment than barcodes, on the other it sure offers greater benefits. Unlike 1D/2D codes, RFID labels can also be rewritten and protected with passwords, thus making it a safer and more reliable tool

These two technologies can still be used in combination though. On RFID tags it is in fact possible to print any type of data; combining RFID tags and 1D / 2D codes allows continuous tracking when it is not possible to use RFID readers, or even in the rare eventuality that the chip is damaged.

Reading performance

Optical technologies allow to read one product code at a time, making operations such as warehouse loading, unloading and inventory long and expensive. With RFID technology it is possible to read over a hundred products simultaneously.

Reading distance

While optical technoloies have a punctual reading range, the RFID reader can detect tags in an area of radius of up to 16m.

Reading speed

Even the reading speed of the RFID readers is astonishing; it is in fact very fast (in the order of ms for the reading of hundreds of tags).

Possibility of reading through objects

RFID tags can be scanned even if they are out of the line of sight, unlike identification systems with optical technologies.

Unique identification

RFID tags have a unique identification code, each object to which it is affixed becomes in fact unique and identifiable, in this way it is possible to trace it along the entire supply chain. Optical technologies do not offer this possibility and usually products of the same type have the same barcode.

Why pick EasyRFID

Choosing a supplier for RFID and tracking technologies require evaluation of many factors.

Wide selection of products

A wide selection of passive tags - UHF, HF, and NFC - is available, in many different shapes and materials, each of which suitable for specific applications.

Internal production

EasyRFID's products are made entirely internally to our company: this allows for high production control and a wide personalization capacity.

Quality

The highly specialized quality control team inspects every single label roll in order to remove the non-working tags and provide 100% functional products.

Samples

We provide custom samples fast and completely compliant to the costumer requests.