Tag rfid wet inlay, RFID labels and hardtags

RFID tags and antennas

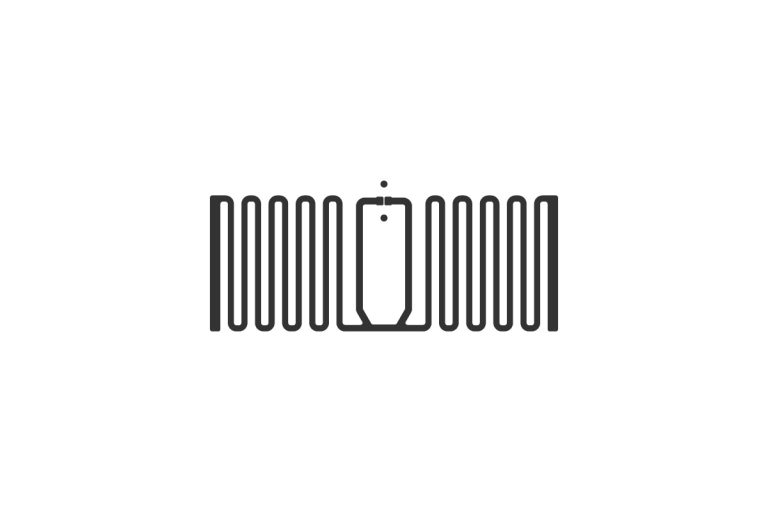

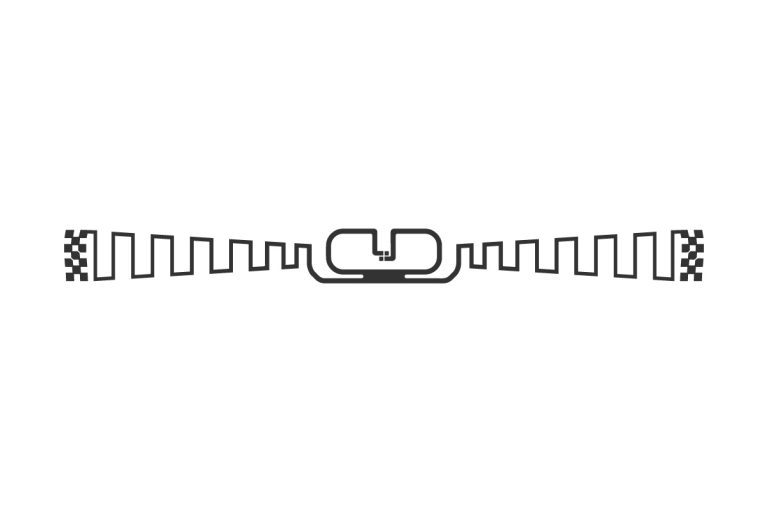

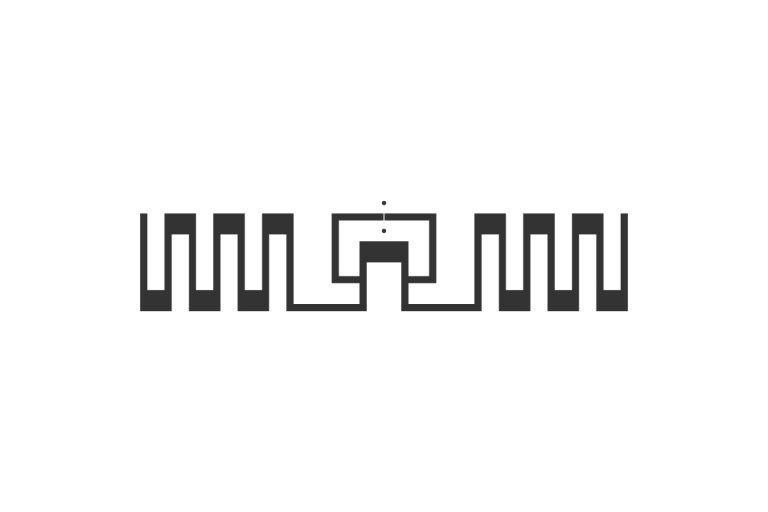

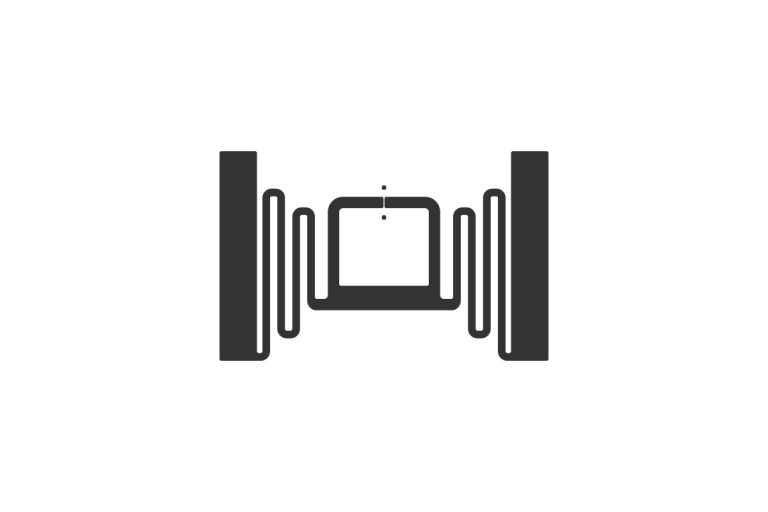

What is a RFID tag and its production

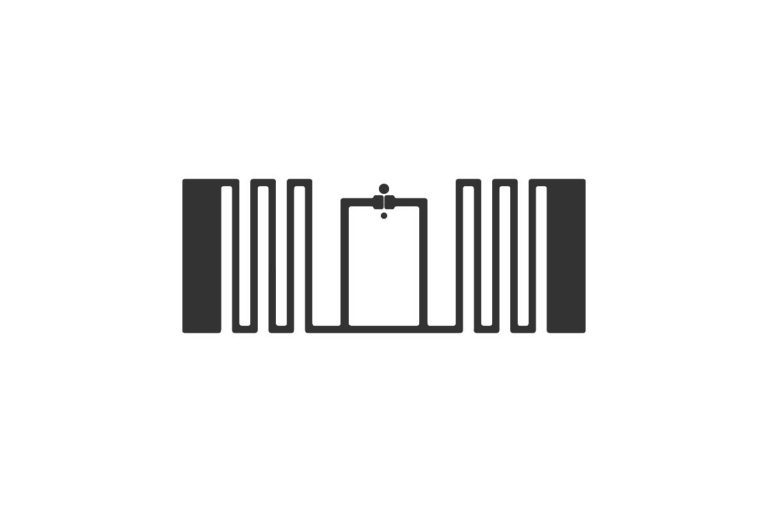

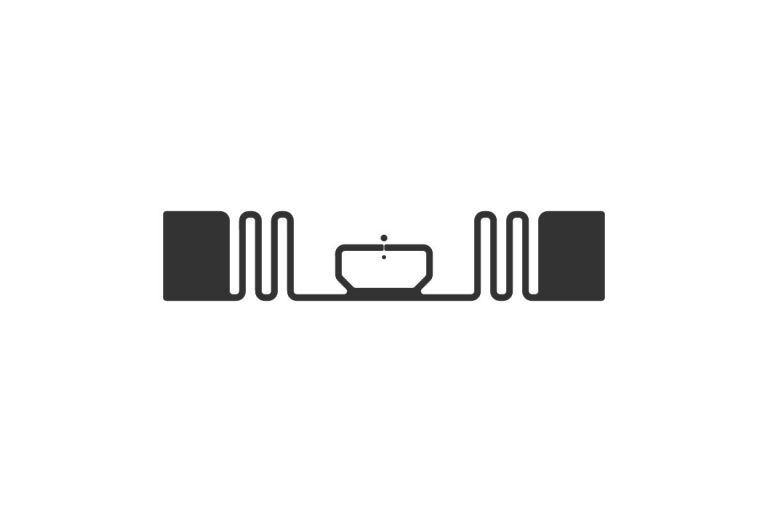

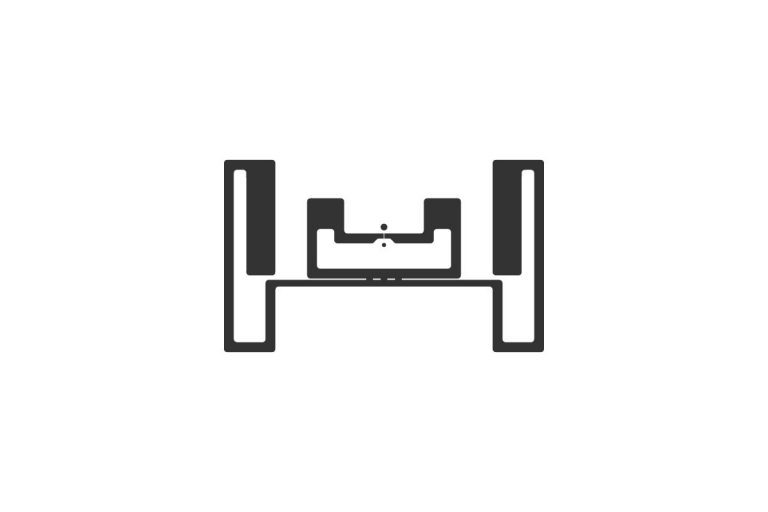

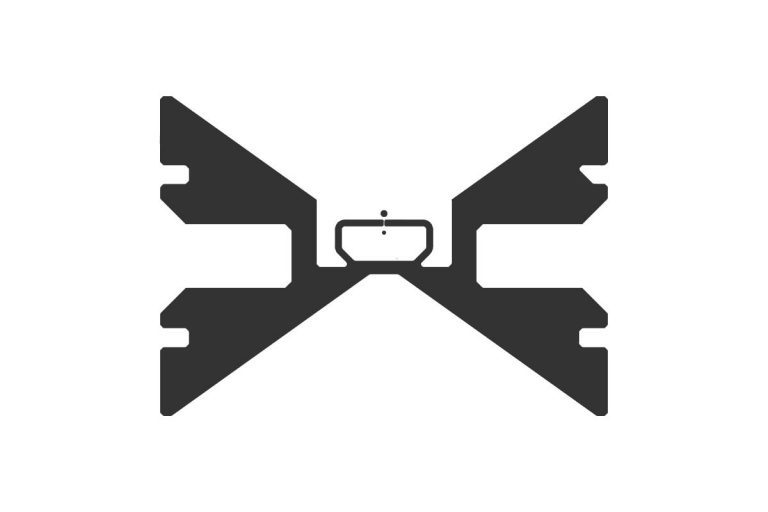

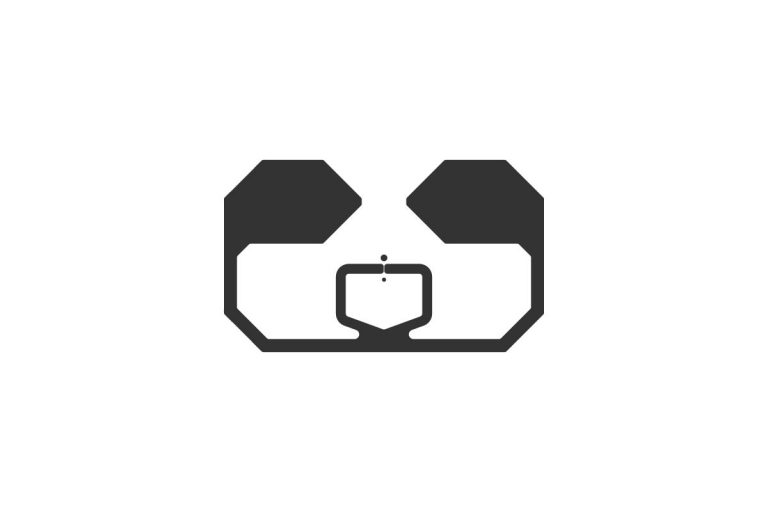

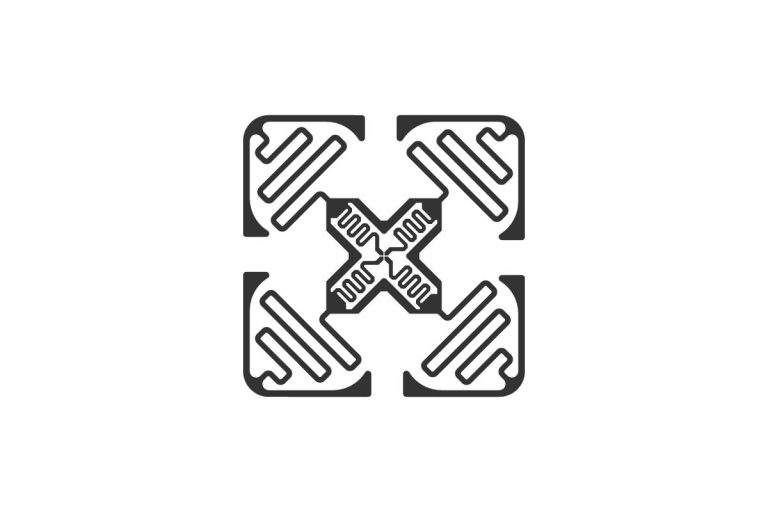

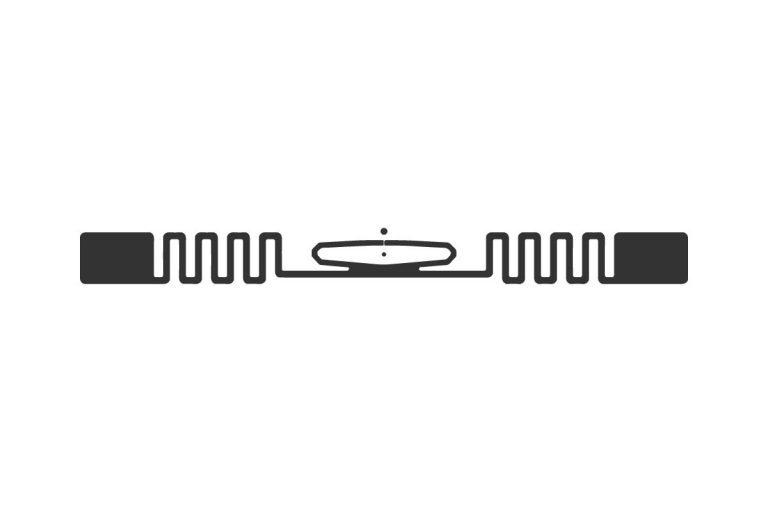

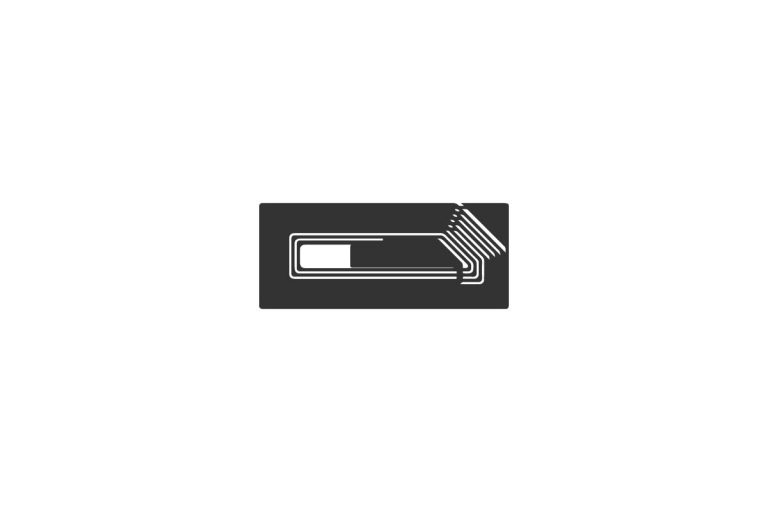

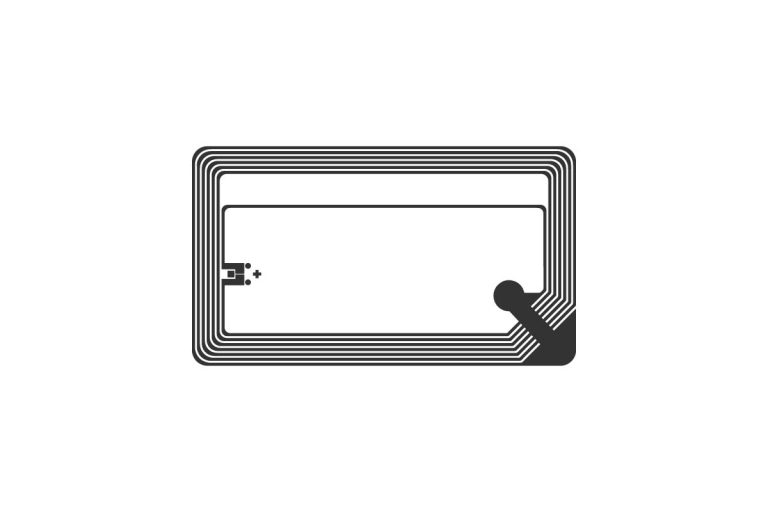

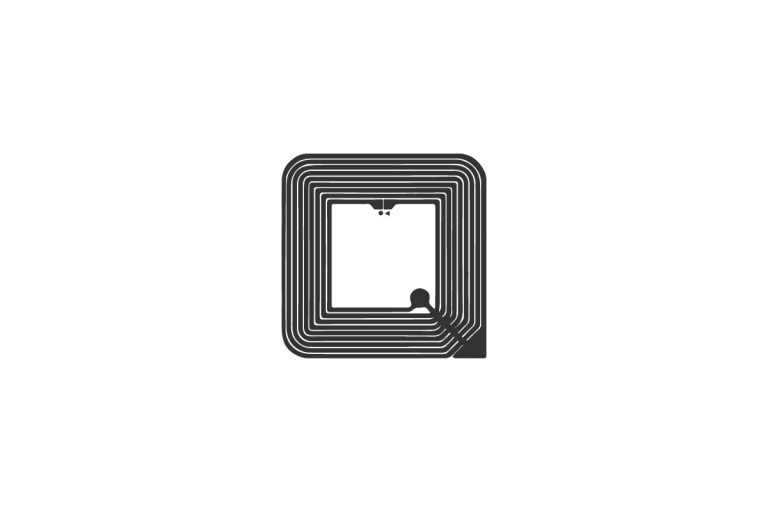

A passive RFID tag is composed of an antenna - a conductive material design also called inlay - and a microchip that retains the data for the identification. EasyRFID manufactures RFID tags from the very beginning of the production: the pick-and-place of the chip on the RFID antenna, starting from the inlay and the UHF, NFC/HF microchip. This allows maximum flexibility when creating a RFID tag or a RFID label that meets the needs of the costumer, other than developing special RFID labels for specific applications.

Some of the production processes are lamination, tooling, inserting of RFID tags in labels, rotation and placing of the RFID tag, and the final processes of customization such as printing and encoding.

Which RFID tag should you choose? Inlay selection depends on its use: some geometries are specific for the application on some materials, so that their reading performance increases strongly. Furthermore, the working frequency of the tags determines three main types of RFID: UHF, HF and LF. Ignoring the latter, the main features of UHF and NFC/HF are:

UHF

UHF tags (Ultra-High Frequency) are commonly used for all of those applications where a large reading area or a long reading distance is required. In fact, these tags can be detected at a distance of up to 16 meters. High reading performance is what makes this technology so appreciated in logistics, waste management and retail.

HF e NFC

I tag NFC (Near Field Communication) - are commonly used for applications in which a reading range of a few centimeters is required. It can be used and written directly from the smartphone, considering that most aveilable devices contain this functionality NFC Tags can be affixed to promotional items, billboards, products and packaging as a customer engagement tool.

Do you want to know more about RFID technology? Click here.

- All

- HF

- Impinj M700 / M800 series

- Impinj Monza 4 series

- Impinj Monza 6 series

- NFC

- NXP ICODE SLIX-2

- NXP NTAG

- NXP UCode 8

- UHF

EasyRFID's special RFID labels

Madre / Figlia

RFID tag associated to a number of daughter labels without tags and printed with data

BIO tag

Biodegradable tag for all of those applications where compostability cannot be spoled

Butterfly Flag

Flag tag perfect for those applciations where the tag risks to be crushed

Outdoor IP68

Rugged IP68 tag for outdoor and extreme applications

Sandwich Tag

Sandwich is a various material tag both for indoor and outdoor labeling

Laundry Soft

Laundry soft is a textile application tag, printable and resistant to washing and dry cleaning

Garbage IP68

IP68 standard tag applied mostly to waste bags and used in waste management

Paper Inlay

Tag with plastic-free paper-support material for ecofriendly applications

Hard-tags for industrial applications

RFID hard-tags are a macro-category of RFID tags, complementary to the flexible tags in roll manufactured by EasyRFID; this type of tags is used when a high mechanical resistance is required, and a rigid case for the tag safety is needed. Hard-tags can be adhesive or fastened; furthermore, it is possible to print the hard-tags, and if needed, protect the print with epoxy.

- on-metal: plastic and ceramic hard-tags that perform best only when applied onto metal surfaces.

- off-metal: hard-tags that can only be applied to non-metal surfaces and that do not work otherwise.

- omni-material: hard-tags that perform well on any type of material.

- high-temperature: hard-tags made of different materials that can endure extremely high temperature - up to 450°C - for long periods of time.