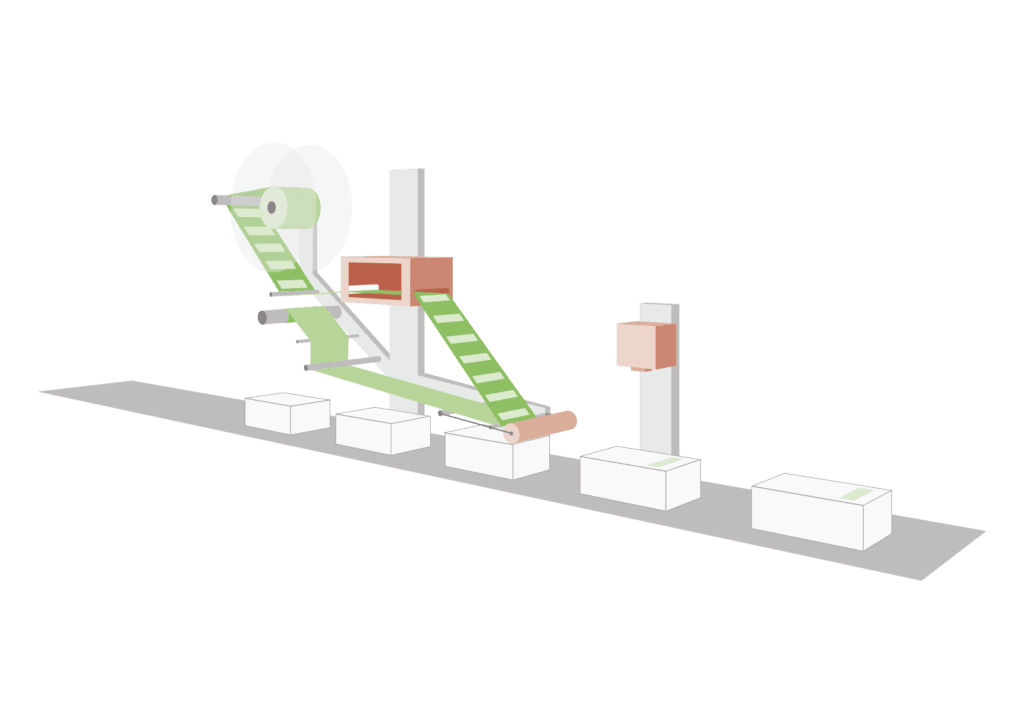

In-line labeling allows to apply RFID tags in an even earlier stage of a tracking solution. The system is not invasive and is fully integrable in pre-existing production lines. Usually, the labeling machine is installed between the phases of production of the item to be tracked, or in a post-production dedicated site.

Sealing: up to IP64

Dimensions: custom

Weight: custom

Configurations: stand alone / in-line automatic / with feeler

Rugged design (up to IP64)

100% Custom

Possible features

Application of labels with automatic removal of not working ones (application of 100% good)

Integrated PLC with multiprotocol data exchange

Exchange consensus via I/O

PLC variables sharing or Rest API

Remote trigger (light sensor / remote)

PC station / in-cloud direct transmission

Application with feeler for uneven surfaces

Application confirmation

Shielding cage

In-line labeling is widely integrated in those sectors in which the labeling process can be automated, guaranteeng high speed and efficiency RFID label application. Along with systems like gates and tunnels, in-line labeling systems allow to acheve the maximum level of tracking and management of the logistic flow; in fact, items are so identified at the level of the production phases.

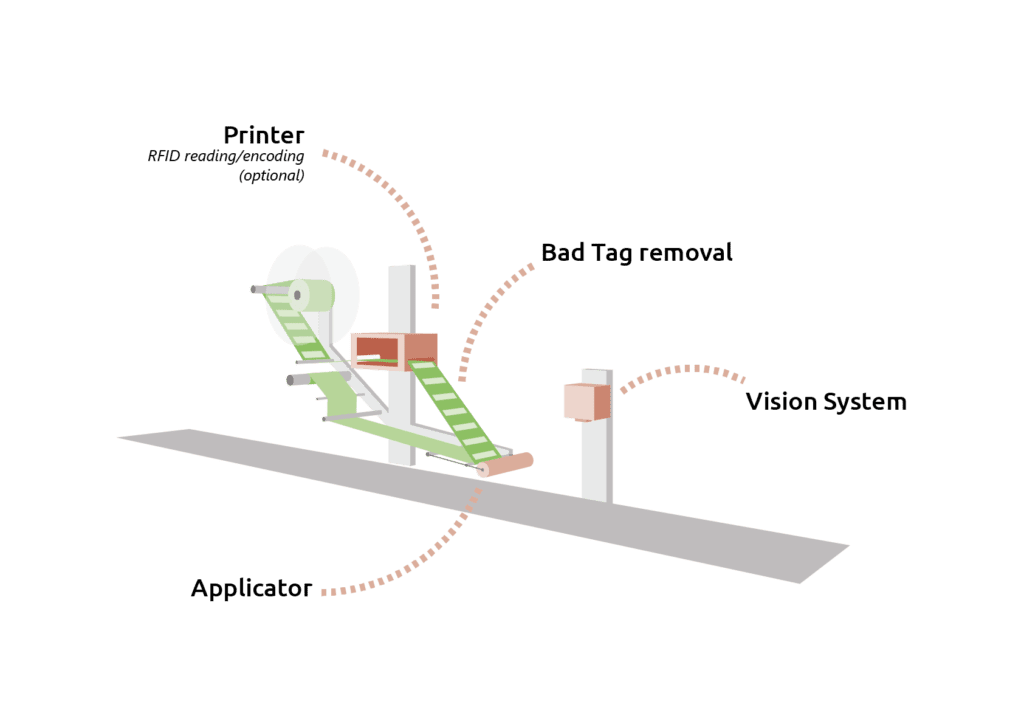

The basic configuration of labelers involve an label applier with a peeler and collection of the used liner; in this case, labels are pre-customized with encoding and printing when manufacturing the RFID label rolls. In case the customization is done at application level, the in-line labeler must also involve a thermal-transfer printer and a RFID reader. In this case, the labeler is connected to the management software or to a dedicated software.

The system can be completed adding components such as vision systems and RFID readers , to gain more control over the label application. These accessories are useful also if a summary of the prcessing and of the processed batch is required, also allowing for the management of the production batches.

The best places for the labeler installation are those where conditions are favorable to the label application; suitability in terms of temperature, cleaniness and transition speed of the item are to be evalued on site.

Easy Srl

Via Galliera, 219 – 40050 Funo di Argelato (BO) – Italy

Via Resistenza, 7/4 – 41011 Campogalliano (MO) – Italy

Via Ianziti s.n.c., 82028 San Bartolomeo in Galdo (BN) – Italy

Phone: +39 051 862369 – Email: info@easyrfid.it