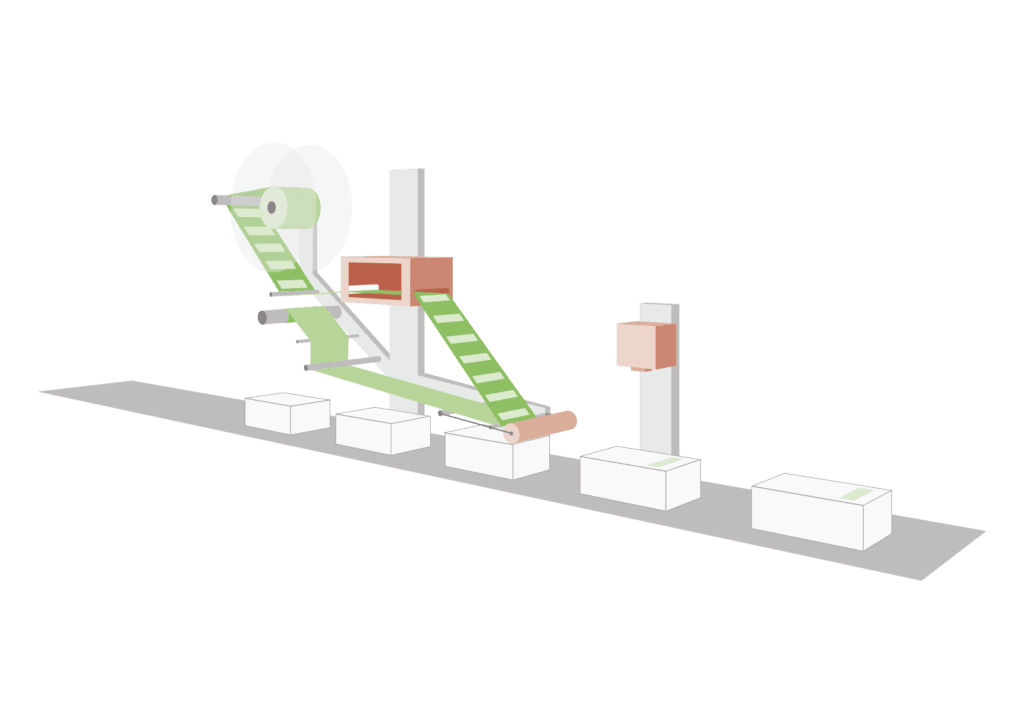

In-line labeling is widely integrated in those sectors in which the labeling process can be automated, guaranteeng high speed and efficiency RFID label application. Along with systems like gates and tunnels, in-line labeling systems allow to acheve the maximum level of tracking and management of the logistic flow; in fact, items are so identified at the level of the production phases.

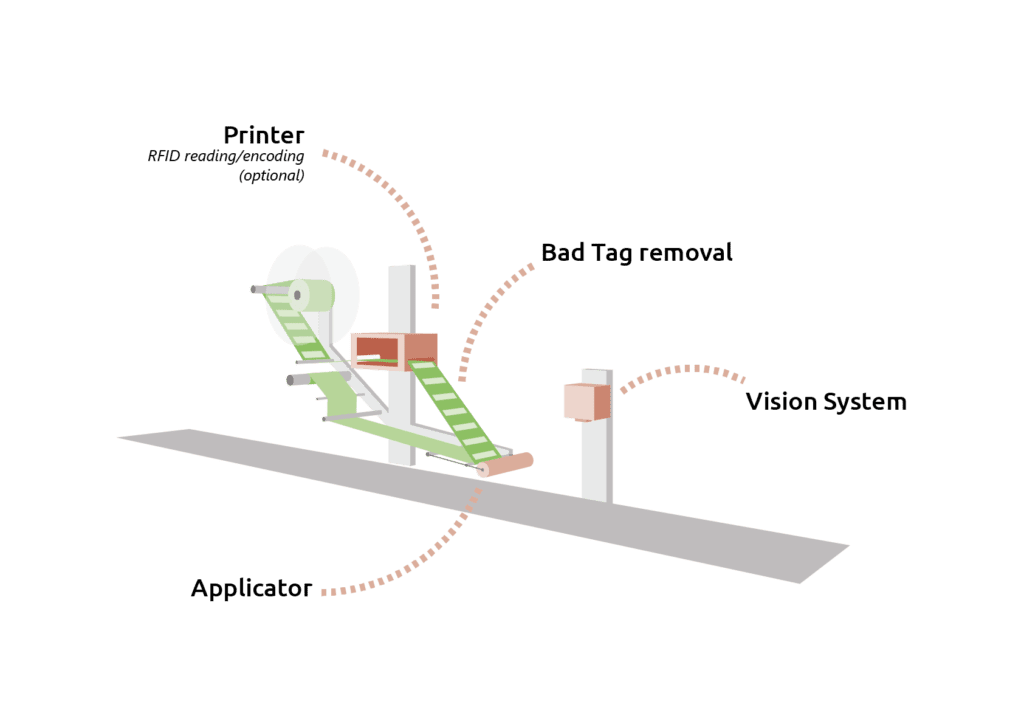

The basic configuration of labelers involve an label applier with a peeler and collection of the used liner; in this case, labels are pre-customized with encoding and printing when manufacturing the RFID label rolls. In case the customization is done at application level, the in-line labeler must also involve a thermal-transfer printer and a RFID reader. In this case, the labeler is connected to the management software or to a dedicated software.

The system can be completed adding components such as vision systems and RFID readers , to gain more control over the label application. These accessories are useful also if a summary of the prcessing and of the processed batch is required, also allowing for the management of the production batches.